When Should You Use a Coil Turner in Your Projects?

Introduction to Coil Turners

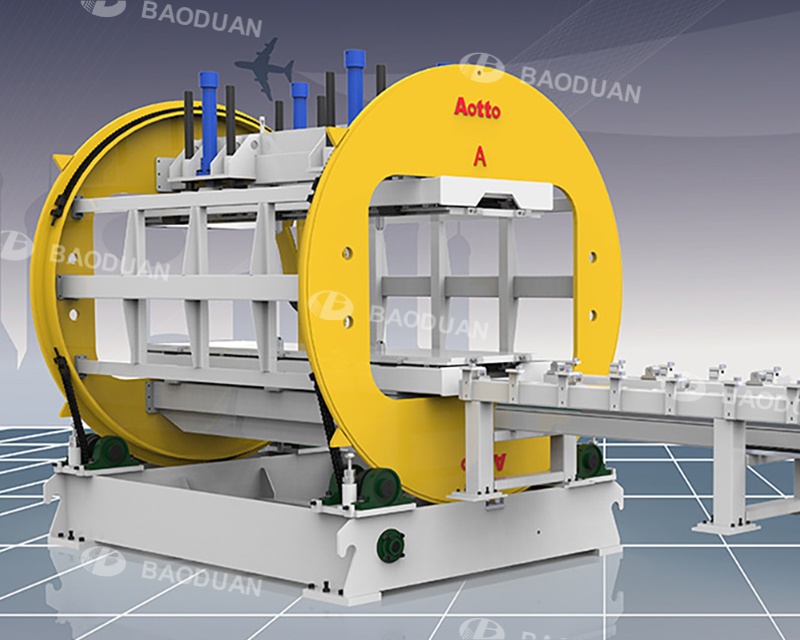

A coil turner is a specialized tool designed to rotate or reposition coils of material during manufacturing or processing operations. These devices play a crucial role in various industries where handling large, heavy, or delicate coils is required. Understanding when to implement a coil turner in your projects can significantly improve efficiency, safety, and product quality while reducing material waste and labor costs.

Coil turners come in different configurations depending on their specific application, including vertical coil turners, horizontal coil turners, and combination units that can handle multiple orientations. The decision to use one depends on several factors related to your material handling needs, production requirements, and operational constraints.

Key Applications for Coil Turners

1. Material Processing Lines

One of the primary applications for coil turners is in continuous material processing lines, particularly in metal and paper industries. When your production process requires changing the orientation of a coil from horizontal to vertical (or vice versa) between processing stages, a coil turner becomes essential.

For example, in steel processing, coils often need to be rotated 90 degrees between the uncoiling and slitting operations. The coil turner ensures proper alignment for the next stage of production without requiring manual intervention or crane operations that could damage the material or create safety hazards.

2. Quality Inspection Requirements

When your quality control procedures mandate inspection of all coil surfaces, a coil turner allows for complete access to the material. Instead of trying to manually rotate heavy coils or relying on imperfect visual inspections, the turner provides controlled rotation that exposes the entire surface area for thorough examination.

This is particularly valuable in industries like aluminum foil production or precision steel manufacturing where surface defects must be identified before further processing or shipment to customers.

3. Space Optimization in Facilities

Coil turners can be instrumental when your facility has space constraints that require efficient material flow. By allowing coils to be stored in one orientation and processed in another, turners enable better utilization of floor space and more streamlined material handling paths.

In compact facilities where storage areas might only accommodate vertical coils but production lines require horizontal feeding (or vice versa), the coil turner serves as the perfect interface between these different spatial requirements.

4. Automated Production Environments

For projects implementing Industry 4.0 principles or high levels of automation, coil turners provide the necessary interface between different automated systems that may require different coil orientations. The turner becomes an integrated component of the automated material handling system, ensuring smooth transitions between processes without human intervention.

This application is particularly valuable in lights-out manufacturing environments or facilities aiming to minimize manual handling of heavy materials.

Technical Considerations for Coil Turner Implementation

1. Coil Dimensions and Weight

The physical characteristics of your coils are primary determinants for whether you need a coil turner. Consider implementing one when:

- Coil weights exceed safe manual handling limits (typically above 1-2 tons)

- Coil diameters are too large for practical manual rotation

- Coil widths require specialized support during rotation

- Multiple coil sizes are processed, requiring adjustable turning solutions

Modern coil turners can handle weights ranging from a few hundred kilograms to over 50 tons, with diameter capacities exceeding 3 meters in some industrial applications.

2. Material Sensitivity

Certain materials require careful handling during rotation to prevent:

- Surface scratches or marring (critical for decorative metals or sensitive coatings)

- Edge damage (important for materials that will undergo further forming processes)

- Deformation (relevant for softer metals or certain composite materials)

If your project involves sensitive materials where improper handling could compromise product quality, a properly designed coil turner with appropriate contact surfaces and rotation control becomes essential.

3. Production Volume and Speed Requirements

High-volume production environments benefit significantly from coil turners when:

- Changeover times between different coil orientations impact overall equipment effectiveness (OEE)

- Manual rotation would create bottlenecks in the production flow

- Multiple orientation changes are required per shift

- Production speeds exceed what manual handling can safely support

The economic justification for a coil turner becomes stronger as production volumes increase and the cost of downtime or slow material handling accumulates.

4. Safety Considerations

Implement a coil turner when manual coil rotation would:

- Expose workers to pinch points or crushing hazards

- Require awkward body positions that increase injury risk

- Involve overhead crane operations in confined spaces

- Necessitate multiple workers for a single rotation task

Coil turners with proper guarding, emergency stops, and controlled motion significantly reduce workplace hazards associated with heavy coil handling.

Economic Factors in Coil Turner Selection

1. Return on Investment Analysis

Justifying a coil turner requires evaluating:

- Labor cost savings from reduced manual handling

- Increased production throughput enabled by faster orientation changes

- Reduced material waste from improved handling

- Lower equipment damage costs from proper coil positioning

- Decreased worker compensation claims from eliminated hazardous manual handling

Projects with frequent coil orientation changes will typically see faster ROI on coil turner investments than those with occasional needs.

2. Maintenance and Operational Costs

Consider the long-term costs associated with:

- Power requirements for the turning mechanism

- Wear parts replacement schedules

- Preventive maintenance needs

- Potential integration with existing material handling systems

Properly specified coil turners from quality manufacturers often prove more economical over their lifecycle despite higher initial costs.

3. Flexibility Requirements

If your project involves:

- Frequent product changeovers

- Variable coil sizes and weights

- Potential future expansion to different materials

- Possible process reconfigurations

Investing in an adjustable or programmable coil turner may provide better long-term value than a single-purpose solution.

Integration with Existing Systems

1. Material Flow Considerations

When integrating a coil turner into your project, evaluate:

- Upstream and downstream equipment interfaces

- Conveyor or transfer system compatibility

- Crane or forklift access requirements

- Floor space allocation for the turning operation

- Potential impacts on overall line speed and synchronization

Proper integration ensures the coil turner enhances rather than disrupts your material flow.

2. Control System Integration

Modern coil turners often feature:

- PLC controls for precise positioning

- HMI interfaces for operator control

- Communication protocols for system integration

- Data collection capabilities for process monitoring

Ensure your project specifications account for these control requirements when the coil turner needs to interface with broader production systems.

3. Safety System Integration

Coil turners must properly integrate with:

- Facility emergency stop systems

- Machine guarding requirements

- Access control systems

- Lockout/tagout procedures

- Area safety monitoring devices

These integrations are particularly critical in automated environments where the turner operates as part of a larger system.

Specialized Applications

1. Precision Industries

In aerospace, medical device, or electronics manufacturing where coil materials require exceptional handling care, specialized coil turners with:

- Clean room compatibility

- Vibration damping

- Precision positioning

- Contamination control

become necessary components of the production process.

2. Heavy Industry Applications

For projects involving:

- Extra-large coil diameters

- Extreme weight capacities

- High-temperature materials

- Corrosive environments

Industrial-grade coil turners with robust construction and specialized features are required.

3. Research and Development Facilities

Even in R&D settings, coil turners prove valuable when:

- Testing new material formulations

- Developing new processing methods

- Prototyping coil-based products

- Evaluating material handling requirements

Smaller-scale or modular coil turners can support these applications without the investment required for full production units.

Future-Proofing Your Investment

When specifying a coil turner for your project, consider:

1. Scalability: Can the unit handle potential future increases in coil size or weight?

2. Adaptability: Is the design flexible enough to accommodate different materials or processes?

3. Technology readiness: Does the turner incorporate features that will remain relevant as technology advances?

4. Maintainability: Are service and parts expected to remain available throughout the equipment's lifespan?

These considerations help ensure your coil turner continues to provide value as your operations evolve.

Conclusion

Implementing a coil turner in your projects becomes advisable when facing challenges with material handling efficiency, product quality maintenance, worker safety, or production bottlenecks related to coil orientation changes. The specific timing depends on your unique combination of coil characteristics, production requirements, facility constraints, and economic factors.

By carefully evaluating your current and anticipated needs against the capabilities of modern coil turning technology, you can make informed decisions that optimize your material handling processes while maximizing return on investment. Whether in high-volume manufacturing, precision industries, or specialized applications, coil turners serve as valuable tools for enhancing operational performance when applied appropriately to project requirements.

يقع Shanghai Baoduan Machinery Manu-facturing Co., LTD في منطقة باوشان في شنغهاي. هو تصنيع المعدات المهنية.

عن

Copynght @ Shanghai Baoduan Machinery Manufacturing Co, LTD. جميع الحقوق محفوظة

خريطة الموقعيستخدم هذا الموقع ملفات تعريف الارتباط لضمان حصولك على أفضل تجربة على موقعنا.

تعليق

(0)